If you’re looking to promote your event or organization, there’s no doubt you’ve considered the use of banners and signage. Many people are not aware that there are many kinds of signs, and not all of them are created equal.

Different types of banners and signs have different uses, and each type has its own advantages and disadvantages. Because of this, we’re going to cover two of the most widely-used and loved types of signage (flex and vinyl printing), what the pros and cons are of each, and how you can decide which one you should be using to promote your business.

Learn the difference between vinyl and flex printing, and make sure to check out our sign company in Houston for all your sign and banner needs!

What is Flex Printing?

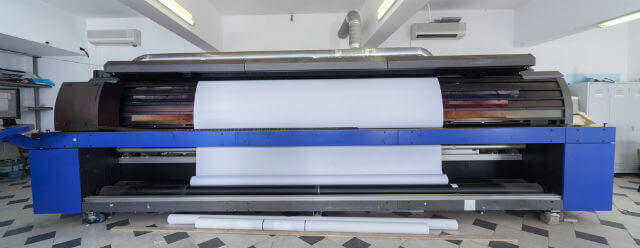

Flex material is softer and more flexible than vinyl. Flex material can be printed on and recolored using specialized industrial printers. These printers basically operate like any other inkjet mechanism, but the printers are designed specifically to accept flex material.

At first glance, flex and vinyl printing can seem very similar; however, they generally have different uses and the materials will appear slightly different under close inspection.

Once flex material has been printed on it can be applied to t-shirts, jackets, sweaters, and flex boards. Flex material is usually attached to these end products by applying heat with special tools or presses that make sure the material is bonded to the surface.

Flex Applications

Other flex printing applications include:

- custom office signs

- point of purchase signage

- trade show displays

- real estate signs

- retail store signs

- business flag banners

What Is Flex Board?

Flex board is a material that is designed specifically to accept the flex material bonding. Flex board printing is the safest and most durable way to apply your printed flex material to a banner or a sign rather than to clothing or other similar mediums.

What is Vinyl Printing?

Vinyl printing is probably the most common kind of banner and signage printing used today. When you use vinyl, you will send your sign maker a pattern or outline with the colors you would like to use. The vinyl is loaded into a special machine and will be cut into the pattern you have selected.

In the past, vinyl could not be recolored with a tool, but new printers have entered the market that can print onto either vinyl or flex materials.

Once your vinyl is cut, it must be applied to an appropriate surface. While flex material is generally applied to a medium using heat, vinyl only needs to be stuck onto your sign or banner using adhesive attached to the vinyl material. The application works just like a band-aid, which needs to have the adhesive covers pulled off before being applied to a surface. Unfortunately, vinyl banners are prone to wrinkling, but learning how to get wrinkles out of vinyl banners is relatively easy.

What Is a Vinyl Poster?

Flex material is the most common kind of printing material used for clothing, though it has been catching on for signage in recent years. Vinyl, is generally only used on signs, banners, and similar surfaces to which that adhesive reliably sticks. Vinyl posters are made of flexible PVC, and the vinyl that is applied to them can stick to the posters for years without ever showing signs of wear. This can also hold true for custom product labels, office signage, and vinyl wall wraps.

Learn more about our poster printing in Houston today!

Final Notes on Flex and Vinyl Printing

In the end, the medium and material you use for your signs and banners are up to you. The most important thing to remember is that flex material is commonly used for clothing and can be slightly more expensive than vinyl. Meanwhile, vinyl is generally used for signs and smooth surfaces.

Whatever you end up choosing, make sure to use Houston Sign to create your Houston banners, and to request a free quote when deciding which option to use!